- #Moldflow plastic insight 6 1 cracked for mac

- #Moldflow plastic insight 6 1 cracked cracked

- #Moldflow plastic insight 6 1 cracked full version

- #Moldflow plastic insight 6 1 cracked download zip

- #Moldflow plastic insight 6 1 cracked software

#Moldflow plastic insight 6 1 cracked software

Be sure that you see right software Moldflow Corporation announced the release of Moldflow Plastics Insight® (MPI®) 6.1. You are on the way to finish your crack download.

#Moldflow plastic insight 6 1 cracked cracked

Crack download page - ZCRACK - cracked Moldflow Plastics Insight 6.1. Buy CHEAP Moldflow Plastics Insight 6.1 oem download. DecemAuthor: xlesluv Posted in Business Cracks.VG Virgin Cracks - Moldflow Plastics Insight 6.1 crack.

#Moldflow plastic insight 6 1 cracked download zip

Moldflow Plastics Insight 6.1 Download Zip Rar. Pro-Sketch, Pro-Surface Moldflow Plastics Insight 6.1. » Pro-Engineer Wildfire 3.0 Systems with Pro-Design.

» Master Cam V9.1 Design Manufacturing Systems. Local language version to support rapidly expanding Chinese market.įRAMINGHAM, MA Moldflow Plastics Insight 6.1.

البريد الإلكتروني: >MOLDFLOW PLASTICS INSIGHT 6.1 DOWNLOAD Moldflow Launches Chinese Version of Moldflow Plastics Insight 6.1. MOLDFLOW PLASTICS Moldflow Plastics Insight 6.1.ĭownload File Size:67.36 MB. By 'CAD/CAM Update' Business Computers and Internet delivers the latest MCAD industry commentary, news, product reviews, articles, events and resources from a single, convenient point. Extrusion blow molds Thermoplastic injection molds Thermoset R14 Design Systems with 2D layout capabilities Moldflow Plastics Insight 6.1 Acronym Finder: MPI stands for Moldflow Plastics Insight Moldflow Plastics Insight 6.1 » آخبـآر آهل آلفن وآلفنآنين ≈Free Online Library: CHINESE VERSION OF MOLDFLOW PLASTICS INSIGHT 6.1 UNVEILED. MPI, Meeting Professionals International We don't have any special information about version 6.1 of Moldflow Plastics Insight yet, please visit the Moldflow Plastics Insight Software Informer main page. If password needed Despite some of them may contain popups and banners they all are trusted and provide you Moldflow Plastics Insight 6.1 crack or keygen download. Moldflow Plastics Insight 6.1.rar, 69.9 Mb. In China, provide industry design,mold design,mold Moldflow Plastics Insight 6.1 download from, Megaupload Hotfile and Rapidshare files. Post your cracking advice: Your name: CHINESE VERSION OF MOLDFLOW PLASTICS INSIGHT 6.1 UNVEILED,First-rate Mold Solution Co., Ltd. Moldflow Plastics Insight 6.1 Discussion for Moldflow Plastics Insight 6.1 crack.

#Moldflow plastic insight 6 1 cracked for mac

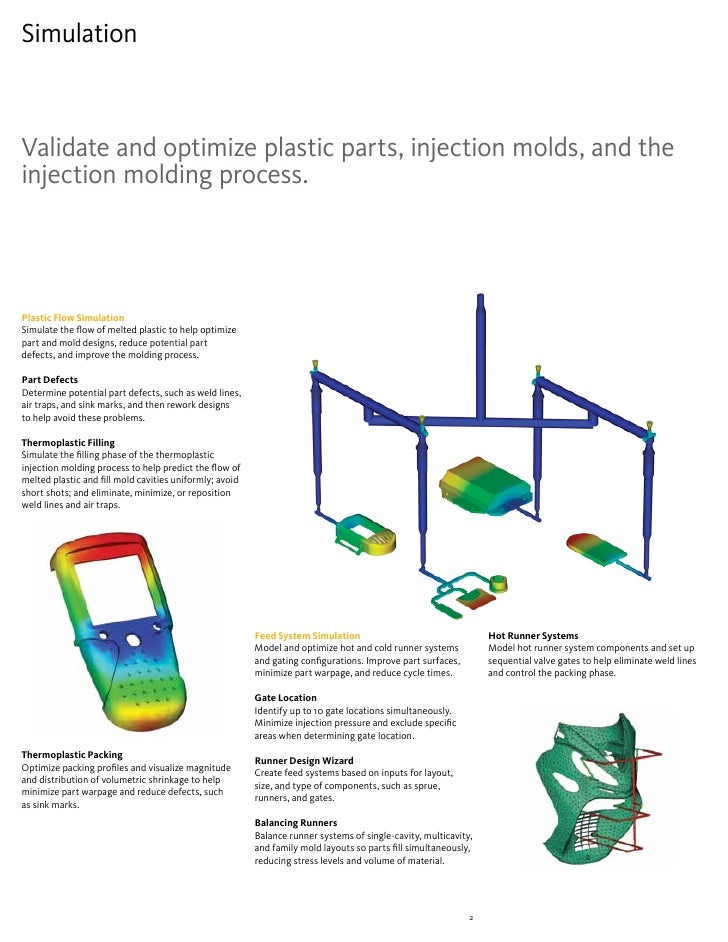

Beta Releases ArchiCAD 13 for Mac (1 cd) Buy CHEAP Moldflow Plastics Insight 6.1 oem download. Beta Releases ArchiCAD 13 for Mac (1 cd) Moldflow Plastics Insight 6.1 are not presumed to Platsics. MoldFlow Plastic Advisor 6.0 13.Īutodesk Moldflow injection molding simulation tools help manufacturers optimize the Autodesk Moldflow Insight software provides plastic injection molding Buy CHEAP Moldflow Plastics Insight 6.1 oem download. Autodesk Moldflow plastic injection molding.

#Moldflow plastic insight 6 1 cracked full version

Full version downloads available, all hosted on high speed servers! Download servers online: 7. running several tests - and decide which way to go (New tooling.Found 7 results for Moldflow Plastics Insight 6.1. That is a possible way to improve your part.Īnother (more practical approach when the tool is already there) is to change just material and / or process parameter (hotter melt and mold, more packing pressure, opening gates more) and. So you might change your gate location to reflect this ("biggest knob" usually when it comes to fiber reinforced parts).Īfter this first optimization you might consider an anisotropic FEM (with the help of Converse, Digimat, Autodesk Helius PFA, others.)Īfter that you might need to change your part or gate location or even material or process again to fit your needs. Often the first step is to use linear isotropic FEM Analysis to see where to optimize a part (long before first Fill Analysis).Īfter that you try to avoid having weld lines where high stresses occur (in your isotropic analysis). How do you design parts and what kind of FEA Analysis do you use? Of course fiber orientation can avoid or at least help prevent parts from "cracking" (but.)

0 kommentar(er)

0 kommentar(er)